What if, for example, a fire had broken out after the Wigle Whiskey boiler explosion and spread to nearby apartments or other businesses? ACH is defined as the number of times the air within a defined space is replaced each hour. The DISCUS manual requires either mechanical or natural ventilation to keep the concentration of vapors in the air at or below 25 percent of the lower flammable limit, or  If whatever's in there doesn't work, somebody could come back and say, 'But you told us to do it this way,' and I have no code to back it up., Bourbon Burn A fire at the Wild Turkey Distillery in 2000 in Lawrenceburg, Kentucky. Sizing the boiler The heating element is 4500 watts, so I think I need 255 CFM (based on Kal's article http://www.theelectricbrewery.com/ventilation ). 0000063327 00000 n

It's not just the storage of spirits that's a hazard. The equipment will typically arrive in an enclosed 53 trailer, standing up and lagged to the floor, or lying down on skids. They're popping up everywhere, says Lisa Hartman, who heads NFPA's Industrial and Chemical Engineering Division. It was getting risky, he says. A great location for brewing beer isnt great without proper ventilation. How you came to a value is pounds would be interesting to know. In a commercial setting this hood would need to be explosion-proof so that free propane could not be 1) What regulations exist that cover brewery dust management in your locality? Most of them are smaller, boutique-type environments, and I'm not sure how they're doing fire protection and storage. WebIf you want to do this by the book, you may need explosion proof electrical components everywhere. Carbon monoxide, or CO, is called the silent killer. It is colorless, odorless, and has the same density as air (meaning it isnt found only close to the floor). Finish setting up your membership at the link below! The co2 is more dense than normal air, so it will fall out and be displaced with outside air every time you open the walk-in door. While Gittleman has pointed clients to the document in the past, he has become so concerned about liability issues related to fire safety at distilleries that he no longer accepts them as clients. Forks should be extendable and padded to protect the equipment. 0000005567 00000 n

Author(s): Angelo Verzoni. This will be expensive. While the distilling industry has been self-regulating for decades, the craft boom raises the question of whether additional guidance can or should be provided by organizations like NFPA. The distilling space houses rows of metal tanks, tubes, pipes, and other equipment, and is separated by glass and thick wooden beams from a tasting room and event space. However, I cannot find any documentation to justify our practices, so we are at an impasse.

If whatever's in there doesn't work, somebody could come back and say, 'But you told us to do it this way,' and I have no code to back it up., Bourbon Burn A fire at the Wild Turkey Distillery in 2000 in Lawrenceburg, Kentucky. Sizing the boiler The heating element is 4500 watts, so I think I need 255 CFM (based on Kal's article http://www.theelectricbrewery.com/ventilation ). 0000063327 00000 n

It's not just the storage of spirits that's a hazard. The equipment will typically arrive in an enclosed 53 trailer, standing up and lagged to the floor, or lying down on skids. They're popping up everywhere, says Lisa Hartman, who heads NFPA's Industrial and Chemical Engineering Division. It was getting risky, he says. A great location for brewing beer isnt great without proper ventilation. How you came to a value is pounds would be interesting to know. In a commercial setting this hood would need to be explosion-proof so that free propane could not be 1) What regulations exist that cover brewery dust management in your locality? Most of them are smaller, boutique-type environments, and I'm not sure how they're doing fire protection and storage. WebIf you want to do this by the book, you may need explosion proof electrical components everywhere. Carbon monoxide, or CO, is called the silent killer. It is colorless, odorless, and has the same density as air (meaning it isnt found only close to the floor). Finish setting up your membership at the link below! The co2 is more dense than normal air, so it will fall out and be displaced with outside air every time you open the walk-in door. While Gittleman has pointed clients to the document in the past, he has become so concerned about liability issues related to fire safety at distilleries that he no longer accepts them as clients. Forks should be extendable and padded to protect the equipment. 0000005567 00000 n

Author(s): Angelo Verzoni. This will be expensive. While the distilling industry has been self-regulating for decades, the craft boom raises the question of whether additional guidance can or should be provided by organizations like NFPA. The distilling space houses rows of metal tanks, tubes, pipes, and other equipment, and is separated by glass and thick wooden beams from a tasting room and event space. However, I cannot find any documentation to justify our practices, so we are at an impasse.  Renew now to keep accessing exclusive seminars, industry statics, the BA forum, and much more! Brewery Ventilation thread403-379650 HVACguy1985 (Mechanical) (OP) 6 Feb 15 19:02 Hi all I am designing brewery that has open fermenters and 1200 lbs/day CO2 produces. Since that water is boiled off over an hour it works out to a very modest 7.57 cubic feet/minute (206 l/min) flow rate which can be handled easily by even a small blower or fan in the vent. Discover how this hybrid manufacturing process enables on-demand mold fabrication to quickly produce small batches of thermoplastic parts. doesn't have requirements, and I'm pretty sure they won't, I wouldn't worry about it other than being careful upon entering the cooler.That's a can of worms better left un-opened. A a very high precision you have with 456.3587 pounds of CO2. Is expansion rate 1600 or 1700? The two things you should be most concerned about are the buildup of carbon monoxide resulting from imperfect combustion and an accumulation of uncombusted propane that could occur if your burner flame went out while propane kept flowing. (fixture type, location and quality) Sanitary fixture requirements for customers and employees shall be permitted to be met with a single set of restrooms. 0000003220 00000 n

Here are a few important design considerations to accommodate your brewery system. While losses from the incident were minimal, it illustrates why there's concern over these facilities: you never know where they're going to pop up. Hot and cold hose bibs are required in all brewery spaces and lab areas. 0000007224 00000 n

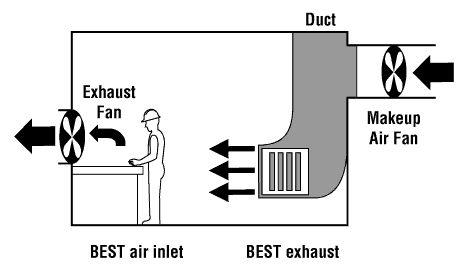

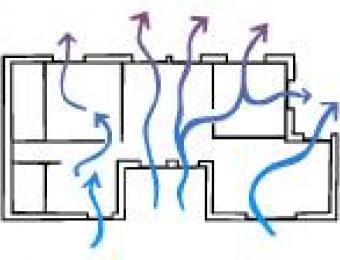

Without proper ventilation, a few brew days a year can cause moisture buildup on your ceiling and walls, resulting in unwanted mold and mildew if you dont address the issue. Planning an Indoor Electric Brewery Part 2 Ventilation The DISCUS manual requires either mechanical or natural ventilation to keep the concentration of vapors in the air at or below 25 percent of the lower flammable limit, or the minimum concentration at which the vapors can ignite in air, which varies based on temperature and alcohol concentration. Already a Member? Another port on the lid will have a hose that vents to the outside. We can discuss a design to meet your project needs. Also check out the How to Brew Video series I shot with John Palmer if you want to learn more about all grain brewing. please help how many Air changer per hour required to be exhausted. The Make-up air is on the roof. Thank you for helping keep Eng-Tips Forums free from inappropriate posts.The Eng-Tips staff will check this out and take appropriate action. But the manual isn't something jurisdictions are in a position to adopt and enforce, since distillers purchase and use it at their own discretion. Metal 3D printing has rapidly emerged as a key technology in modern design and manufacturing, so its critical educational institutions include it in their curricula to avoid leaving students at a disadvantage as they enter the workforce. The lack of guidance within commonly used codes and standards has led to a lack of knowledge among craft distillers and the fire service around some of the dangers of these facilities, according to Gerczysnki. It may not display this or other websites correctly. If a steam fired system is selected, an exhaust flue is required in the boiler room for the gas-fired boiler.

Renew now to keep accessing exclusive seminars, industry statics, the BA forum, and much more! Brewery Ventilation thread403-379650 HVACguy1985 (Mechanical) (OP) 6 Feb 15 19:02 Hi all I am designing brewery that has open fermenters and 1200 lbs/day CO2 produces. Since that water is boiled off over an hour it works out to a very modest 7.57 cubic feet/minute (206 l/min) flow rate which can be handled easily by even a small blower or fan in the vent. Discover how this hybrid manufacturing process enables on-demand mold fabrication to quickly produce small batches of thermoplastic parts. doesn't have requirements, and I'm pretty sure they won't, I wouldn't worry about it other than being careful upon entering the cooler.That's a can of worms better left un-opened. A a very high precision you have with 456.3587 pounds of CO2. Is expansion rate 1600 or 1700? The two things you should be most concerned about are the buildup of carbon monoxide resulting from imperfect combustion and an accumulation of uncombusted propane that could occur if your burner flame went out while propane kept flowing. (fixture type, location and quality) Sanitary fixture requirements for customers and employees shall be permitted to be met with a single set of restrooms. 0000003220 00000 n

Here are a few important design considerations to accommodate your brewery system. While losses from the incident were minimal, it illustrates why there's concern over these facilities: you never know where they're going to pop up. Hot and cold hose bibs are required in all brewery spaces and lab areas. 0000007224 00000 n

Without proper ventilation, a few brew days a year can cause moisture buildup on your ceiling and walls, resulting in unwanted mold and mildew if you dont address the issue. Planning an Indoor Electric Brewery Part 2 Ventilation The DISCUS manual requires either mechanical or natural ventilation to keep the concentration of vapors in the air at or below 25 percent of the lower flammable limit, or the minimum concentration at which the vapors can ignite in air, which varies based on temperature and alcohol concentration. Already a Member? Another port on the lid will have a hose that vents to the outside. We can discuss a design to meet your project needs. Also check out the How to Brew Video series I shot with John Palmer if you want to learn more about all grain brewing. please help how many Air changer per hour required to be exhausted. The Make-up air is on the roof. Thank you for helping keep Eng-Tips Forums free from inappropriate posts.The Eng-Tips staff will check this out and take appropriate action. But the manual isn't something jurisdictions are in a position to adopt and enforce, since distillers purchase and use it at their own discretion. Metal 3D printing has rapidly emerged as a key technology in modern design and manufacturing, so its critical educational institutions include it in their curricula to avoid leaving students at a disadvantage as they enter the workforce. The lack of guidance within commonly used codes and standards has led to a lack of knowledge among craft distillers and the fire service around some of the dangers of these facilities, according to Gerczysnki. It may not display this or other websites correctly. If a steam fired system is selected, an exhaust flue is required in the boiler room for the gas-fired boiler.  Your brewing burners are not really comparable to a gas stoves burners, neither in design nor in the amount of petroleum gas they use. One of the most dangerous aspects of distilling, Gerczysnki says, are the alcohol vapors that not only can emanate from the distilling equipment, but also from the barrels or casks of stored distillates. I am looking at your numbers and can not make any sens of them. Photographs: Top, Angelo Verzoni; Bottom, NFPA Conference & Expo Presentation, Rack-stored Distilled Spirits Storage Protection 2018 FM Global. Uniform water flow to the brewhouse is critical and should not be affected by water demand elsewhere in the building. In part 1 of this series I covered some of the general considerations in planning an electric brewery including size of the system, availability of water and in particular the electrical needs of the system and electrical safety considerations. However a 10+ gal (38+) liter system in an enclosed room down in a humid basement may be a real problem. Phillip Kelm--Palau Brewing Company Manager--. That was when we generated the new programs for research targeting palletized and rack storage of wooden barrels filled with 70 percent ABV liquid. The FM Global research shows that, while fire sprinklers are typically effective at suppressing flames for rack-stored spirits where barrels are stored on their sides, wide flue spaces are essential in palletized configurations where barrels are stored upright. Thus a 600 cfm vent fan would be required. Please let us know here why this post is inappropriate. However the venting of the heat and steam is not the whole story, as you also need to consider the size and efficiency of your hood. A 5 gal (19 l) system puts out about half that. Gittleman's point gets to the crux of the issueeven though authorities having jurisdiction (AHJs) might recognize the risk posed by distilleries in their areas, they have little to reference to enforce fire-safe practices. This can lead to mold, permanent damage to the drywall, and other nasty issues. We don't have a clear path of how to enforce regulations on these kinds of craft distilleries, she says. *Eng-Tips's functionality depends on members receiving e-mail. You are using an outdated browser not supported by The Brewers Association. In a closed space you will get heavy condensation on the ceiling, walls, windows, floors and even between walls. brewing, Ryan Oxton is the Market Development Manager at Spike. We can discuss the requirements prior to finalizing a design. trailer

<<

/Size 137

/Info 103 0 R

/Root 110 0 R

/Prev 224894

/ID[<13aa9602b7d258bf9f8fdc7f9e8891e4>]

>>

startxref

0

%%EOF

110 0 obj

<<

/Type /Catalog

/Pages 101 0 R

/Metadata 108 0 R

/PageLabels 99 0 R

/FICL:Enfocus 104 0 R

>>

endobj

135 0 obj

<< /S 458 /L 661 /Filter /FlateDecode /Length 136 0 R >>

stream

Victoria, BC Canada V8M 1Z9 | P. 250 652 2111 | sales@specific.net | Privacy Policy. FM Global, whose clients include whiskey makers, began research into fire protection and storage configurations for distilled spirits about five years ago. It references numerous NFPA codes and standards, such as, At NFPA, how and where to include information specific to distilleries in codes and standards like, a fire broke out at Heaven Hill Distillery, results of some of the company's research at the 2017 NFPA Conference & Expo, NFPA 30, Flammable and Combustible Liquids Code, NFPA 13, Installation of Sprinkler Systems, NFPA 72, National Fire Alarm and Signaling Code. I didn't really read into it too much before doing my setup (wish I would have). Malt drying ventilation has the following specific requirements (1) There should be a reasonable ventilation device for drying furnace to save energy. 0000002337 00000 n

Equipment Q&A (Sponsored by Standard Kegs), If this is your first visit, be sure to check out the. Fueled by the storms whipping winds, flames from the burning spirit shot skyward and formed a massive fire whirl over the pond that was captured on video and later widely shared online, where sensationalized headlines dubbed it a firenado. No one was hurt in the incident, although the Weather Channel reported the casualties of many fish.. 0000012928 00000 n

Do you think 0.3 ACH is enough? The fermentation process produces a large amount of CO2. ASHRAE has a standard of 1,000 ppm CO2 for indoor spaces. Gerczysnki is also part of the group. Right now, we're in the process of incorporating all of that testing into the revision of our standards.. According to data in a 2005 version of the fire protection manual created by the Distilled Spirits Council of the United States (DISCUS), pure ethanolthe alcohol present in spirits, beer, and winereleases more than half the energy of 100-octane gasoline when it burns; the gasoline releases 20,750 BTU per pound, while ethanol releases 12,800 BTU per pound. hood, 456.3587 Total pounds of CO2 released per day at full capacity. All we need to do is take a look at the amount of water boiled off during an average brewing session to see that the steam needs somewhere to go. Tagged as: And just because we havent seen a fatality at a nano, does not mean it cannot happen. Please state the time that it takes to complete the fermentation that produces CO2 during the batch process. If the idea of ventilation sounds good, but having another project to tackle doesnt, there are cost-effective accessories like steam condenser lids that can do the job While the ventilation requirements for an electric brewing system are far below what is needed for a gas/propane heated system, proper venting is still important. Webbrewery function, including, but not limited to, the brewhouse, boiling and water treatment areas, bottling and kegging lines, malt milling and storage, fermentation tanks, conditioning "This stuff can be really dangerous if you don't know what you're doing., ANGELO VERZONI is staff writer for NFPA Journal. The following guidelines may be applied as general specifications for brewpubs. Please consider upgrading! Your understanding of "significant figures" reveals something of your engineering skills. Soon you have beautiful, rolling bubbles and plumes of steam and youre on the road to making your next great beer! sorry. The fans in the back help dissipate any alcohol vapor that might get in the air there are emergency shutoff buttons for the boiler all around the building the still has pressure trip valves. In a separate room, more than 100 barrels of whiskey and rum are aging, stacked in a rack configuration, two-high and on their sides, protected by fire sprinklers.

Your brewing burners are not really comparable to a gas stoves burners, neither in design nor in the amount of petroleum gas they use. One of the most dangerous aspects of distilling, Gerczysnki says, are the alcohol vapors that not only can emanate from the distilling equipment, but also from the barrels or casks of stored distillates. I am looking at your numbers and can not make any sens of them. Photographs: Top, Angelo Verzoni; Bottom, NFPA Conference & Expo Presentation, Rack-stored Distilled Spirits Storage Protection 2018 FM Global. Uniform water flow to the brewhouse is critical and should not be affected by water demand elsewhere in the building. In part 1 of this series I covered some of the general considerations in planning an electric brewery including size of the system, availability of water and in particular the electrical needs of the system and electrical safety considerations. However a 10+ gal (38+) liter system in an enclosed room down in a humid basement may be a real problem. Phillip Kelm--Palau Brewing Company Manager--. That was when we generated the new programs for research targeting palletized and rack storage of wooden barrels filled with 70 percent ABV liquid. The FM Global research shows that, while fire sprinklers are typically effective at suppressing flames for rack-stored spirits where barrels are stored on their sides, wide flue spaces are essential in palletized configurations where barrels are stored upright. Thus a 600 cfm vent fan would be required. Please let us know here why this post is inappropriate. However the venting of the heat and steam is not the whole story, as you also need to consider the size and efficiency of your hood. A 5 gal (19 l) system puts out about half that. Gittleman's point gets to the crux of the issueeven though authorities having jurisdiction (AHJs) might recognize the risk posed by distilleries in their areas, they have little to reference to enforce fire-safe practices. This can lead to mold, permanent damage to the drywall, and other nasty issues. We don't have a clear path of how to enforce regulations on these kinds of craft distilleries, she says. *Eng-Tips's functionality depends on members receiving e-mail. You are using an outdated browser not supported by The Brewers Association. In a closed space you will get heavy condensation on the ceiling, walls, windows, floors and even between walls. brewing, Ryan Oxton is the Market Development Manager at Spike. We can discuss the requirements prior to finalizing a design. trailer

<<

/Size 137

/Info 103 0 R

/Root 110 0 R

/Prev 224894

/ID[<13aa9602b7d258bf9f8fdc7f9e8891e4>]

>>

startxref

0

%%EOF

110 0 obj

<<

/Type /Catalog

/Pages 101 0 R

/Metadata 108 0 R

/PageLabels 99 0 R

/FICL:Enfocus 104 0 R

>>

endobj

135 0 obj

<< /S 458 /L 661 /Filter /FlateDecode /Length 136 0 R >>

stream

Victoria, BC Canada V8M 1Z9 | P. 250 652 2111 | sales@specific.net | Privacy Policy. FM Global, whose clients include whiskey makers, began research into fire protection and storage configurations for distilled spirits about five years ago. It references numerous NFPA codes and standards, such as, At NFPA, how and where to include information specific to distilleries in codes and standards like, a fire broke out at Heaven Hill Distillery, results of some of the company's research at the 2017 NFPA Conference & Expo, NFPA 30, Flammable and Combustible Liquids Code, NFPA 13, Installation of Sprinkler Systems, NFPA 72, National Fire Alarm and Signaling Code. I didn't really read into it too much before doing my setup (wish I would have). Malt drying ventilation has the following specific requirements (1) There should be a reasonable ventilation device for drying furnace to save energy. 0000002337 00000 n

Equipment Q&A (Sponsored by Standard Kegs), If this is your first visit, be sure to check out the. Fueled by the storms whipping winds, flames from the burning spirit shot skyward and formed a massive fire whirl over the pond that was captured on video and later widely shared online, where sensationalized headlines dubbed it a firenado. No one was hurt in the incident, although the Weather Channel reported the casualties of many fish.. 0000012928 00000 n

Do you think 0.3 ACH is enough? The fermentation process produces a large amount of CO2. ASHRAE has a standard of 1,000 ppm CO2 for indoor spaces. Gerczysnki is also part of the group. Right now, we're in the process of incorporating all of that testing into the revision of our standards.. According to data in a 2005 version of the fire protection manual created by the Distilled Spirits Council of the United States (DISCUS), pure ethanolthe alcohol present in spirits, beer, and winereleases more than half the energy of 100-octane gasoline when it burns; the gasoline releases 20,750 BTU per pound, while ethanol releases 12,800 BTU per pound. hood, 456.3587 Total pounds of CO2 released per day at full capacity. All we need to do is take a look at the amount of water boiled off during an average brewing session to see that the steam needs somewhere to go. Tagged as: And just because we havent seen a fatality at a nano, does not mean it cannot happen. Please state the time that it takes to complete the fermentation that produces CO2 during the batch process. If the idea of ventilation sounds good, but having another project to tackle doesnt, there are cost-effective accessories like steam condenser lids that can do the job While the ventilation requirements for an electric brewing system are far below what is needed for a gas/propane heated system, proper venting is still important. Webbrewery function, including, but not limited to, the brewhouse, boiling and water treatment areas, bottling and kegging lines, malt milling and storage, fermentation tanks, conditioning "This stuff can be really dangerous if you don't know what you're doing., ANGELO VERZONI is staff writer for NFPA Journal. The following guidelines may be applied as general specifications for brewpubs. Please consider upgrading! Your understanding of "significant figures" reveals something of your engineering skills. Soon you have beautiful, rolling bubbles and plumes of steam and youre on the road to making your next great beer! sorry. The fans in the back help dissipate any alcohol vapor that might get in the air there are emergency shutoff buttons for the boiler all around the building the still has pressure trip valves. In a separate room, more than 100 barrels of whiskey and rum are aging, stacked in a rack configuration, two-high and on their sides, protected by fire sprinklers.  Explore the Brewers Association's most high-value resources and tools in one click.

Explore the Brewers Association's most high-value resources and tools in one click.  Copyright 2023 Specific Mechanical Systems Ltd. Main water supply to your brewery is recommended to be 60 psi @ 25 30 GPM. Hi All, I'm designing an exhaust system in brewery. It's a Brewery (production of beer). Published on March 1, 2018. Or a brewing association has guidelines on ventilation. That covers the basics of ventilation. Per day means 24 hours of continuous fermentation. Below 1000ppm is the comfort zone so that headache, nausea, drowsiness do not occur for most people. You also acknowledge that this forum may be hosted outside your country and you consent to the collection, storage, and processing of your data in the country where this forum is hosted.

Copyright 2023 Specific Mechanical Systems Ltd. Main water supply to your brewery is recommended to be 60 psi @ 25 30 GPM. Hi All, I'm designing an exhaust system in brewery. It's a Brewery (production of beer). Published on March 1, 2018. Or a brewing association has guidelines on ventilation. That covers the basics of ventilation. Per day means 24 hours of continuous fermentation. Below 1000ppm is the comfort zone so that headache, nausea, drowsiness do not occur for most people. You also acknowledge that this forum may be hosted outside your country and you consent to the collection, storage, and processing of your data in the country where this forum is hosted.  The figure is much lower for ethanol-water solutions measuring 40 percent ABVthe level of alcohol present in 80-proof distilled spiritsat about 4,300 BTU per pound. 0000002765 00000 n

Click here to setup a resource meeting with Graham, the BA's Engagement Coordinator. By joining you are opting in to receive e-mail. FYI, We are brewing into a 15 bbl brewhouse with plans for a 30bbl system in the future. In 1996, FM Global, whose clients include whiskey makers, began research into fire protection and storage configurations for distilled spirits about five years ago. 3) What is the best practice/equipment for removing the dust from the air? OSHA rules on respiratory protection can also come into play, as malt dust is irritating to the lungs and mucous membranes. 0000004824 00000 n

Based on the information that I provided you, you'll need a ventilation rate of at least 33,845 cu.ft./hr under steady state conditions. Thats something you didnt plan for when you designed your brewery and it will certainly lead to problems.

The figure is much lower for ethanol-water solutions measuring 40 percent ABVthe level of alcohol present in 80-proof distilled spiritsat about 4,300 BTU per pound. 0000002765 00000 n

Click here to setup a resource meeting with Graham, the BA's Engagement Coordinator. By joining you are opting in to receive e-mail. FYI, We are brewing into a 15 bbl brewhouse with plans for a 30bbl system in the future. In 1996, FM Global, whose clients include whiskey makers, began research into fire protection and storage configurations for distilled spirits about five years ago. 3) What is the best practice/equipment for removing the dust from the air? OSHA rules on respiratory protection can also come into play, as malt dust is irritating to the lungs and mucous membranes. 0000004824 00000 n

Based on the information that I provided you, you'll need a ventilation rate of at least 33,845 cu.ft./hr under steady state conditions. Thats something you didnt plan for when you designed your brewery and it will certainly lead to problems.  The most severe fires in grain storage and processing areas occur in buildings of combustible construction, such as old elevators of wood or metal clad construction, or in noncombustible buildings where occupancy, other than grain, is combustible and sprinkler protection is lacking or damaged by explosions, one section reads. Need some additional guidance? kegging/bottling). All drains, plumbing and water lines are prepared to accept brewing equipment. In addition you need to consider venting some of the heat coming from the pot to avoid raising the temperature excessively in the room, again creating a condensation risk. As the temperature of the fire increased, the spirit casks in the warehouse had begun to rupture. So for example a 2 gal/hour (4 l/hour) boil off would produce 1600 times that volume in steam or 3,400 gallons (13,600 liters) of steam. For additional details, refer to our Privacy Policy. Similar scenarios have played out at other distilleries in Kentucky, which is home to many of the countrys largest whiskey makers. Although the Heaven Hill Distillery fire of 1996 was a massive blaze, jumping from one warehouse to another and decimating what was at the time two percent of the world's whiskey stock, it burned only on the facility's sweeping plot of rural Kentucky land. All drains should be sized adequately to handle 4-6 barrels of effluent for every 1 barrel of beer produced. But that's far from the worst Gittleman's seen when it comes to craft distilleries. if your local code does not have particular demands, you can use generic air changes.

2. Whichever solution you choose, just make sure you keep the moisture off your walls and in your beer. > 95% of the CO2 produced during fermentation is released in the first 4 days. Production brewery/microbrewery spaces can vary greatly. A great resource from Georgia Tech can be found here. Upland Brewing Wood Shop Barrel Storage Since CO2 is heavier than air, the air flow should be directed more along the floor area where the work would be conducted and that work environment will have a lesser volume than that of the room. These little craft distilleries can go almost anywhere, says LeBlanc, who also chairs the NFPA 30, Flammable and Combustible Liquids Code, technical committee. http://files.engineering.com/getfile.aspx?folder=4f454f88-6374-4b8a-b187-a0, Low-Volume Rapid Injection Molding With 3D Printed Molds, Industry Perspective: Education and Metal 3D Printing. airflow, Venting into the inner space electric brewery, This should be confirmed by sampling the actual vapor concentration under normal operating conditions, the document reads. 0000006524 00000 n

456.3587 Total pounds of co2 released per day at full capacity. Join your peers on the Internet's largest technical engineering professional community.It's easy to join and it's free. WebAir shall not be exhausted into an attic, soffit, ridge vent or crawl space. Some folks get around this by wet milling, which also has the potential to increase your yeilds. Click Here to join Eng-Tips and talk with other members! 0000001714 00000 n

The best practice for avoiding a dust explosion is thorough and regular housekeeping. Located in a 160-year-old post-and-beam mill building near downtown Boston, the distillery has been producing rye whiskey and other spirits for the past three years. Beer, My concern is the elevated level of carbon dioxide during the fermentation process. Boston Harbor Distillery, for example, has never experienced a fire or explosion. So a small size 2 ft x 2 ft hood would need at least 200 cubic ft/min throughput, and a larger 4 ft x 2 ft hood would need double that or 400 cubic ft/min. homebrew, Make-up air is required in the boiler room on a steam-fired system and in the brewhouse area for a direct gas-fired system. This ebook covers tips for creating and managing workflows, security best practices and protection of intellectual property, Cloud vs. on-premise software solutions, CAD file management, compliance, and more. 2) How do you know the rate of dust creation from your mill? The DISCUS fire protection manual, a product of input from large distillers like Jim Beam, provides a lot of this information in a relatively easy-to-digest manner. When hes not guiding aspiring homebrewers with their first systems or working with breweries as they upgrade their operations, he enjoys spending time with family and losing the occasional golf ball or two. Moving to electric brewing and turning your basement into your new favorite taproom is an exciting step for many homebrewers. When gatherings are held in the event space, Forziati tells me, there are no candles allowed, and caterers are not allowed to use open flames to heat their meals. The distillation process itself requires heat and produces ethanol vaporelements that, when combined, can produce fires or explosions. Even in a fairly sizable enclosed room that 2 gal (8 l) of water is enough to raise the relative humidity in the room by 50% or more all within the space of about 90 minutes! Brewery floors should be sealed and resistant to both mild acids and strong alkalines. Besides location, there are also concerns over who owners are willing to let inside the facilities. Be sure to sign up for my newsletter or my podcast (also on itunesand youtubeandstreaming radio station) for more great tips on homebrewing. At the low end is a completely enclosed boiler of the type you would see in a craft brewery. 0000003319 00000 n

The hood needs to be large enough to capture the steam and also you need sufficient airflow to move the steam collected out of the hood before it spills out of the hood. What are the ventilation requirements for malt drying? We process personal data about users of our site, through the use of cookies and other technologies, to deliver our services, personalize advertising, and to analyze site activity. If our team is performing the installation of your brewery system, we want to ensure the process is performed as efficiently and effectively as possible. Please Advice. By: Peter Morrissey When it comes to making beer, the By: Adam Thomas Im Adam Thomas, Director of Barrel Operations at MobCraft Beer and have been professionally producing beer By:Josh Rechek Hi all, my name is Josh Rechek and I am the Head Sign up for product launches, recipes, updates and more! So the requirement for proper airflow through the hood is actually larger than the airflow dictated by the heating coil alone. Flashpoints, or the temperature at which liquids give off enough vapor to ignite in air, also shed light on the dangers of distilling. There's so much alcohol vapor in the air at some distilleries that they've implemented methods to collect and reuse it. 0000001030 00000 n

Although the rapid expansion of the craft or microbrew industry topped off a few years ago, the United States remains on pace to add thousands of breweries across the country, according to the Brewers Association. Finish setting up your membership at the link below! When the distillery was being built, NFPA codes and standards like NFPA 13 were used, as was the DISCUS fire protection manual. 6848 Kirkpatrick Cres. I will note that some commercial systems lack the blower, which can create condensation in the vent pipe that can drop back into the boil creating DMS. Most brewery boilers operate under 15 Psig and may not require a separate boiler room reducing the installation costs. I said, 'Unless you want to buy a lot of expensive fire-rated glass, you will not be able to get building department approval,' he says. Thank you Drazen. the project located in NYC. the floor area is 5600 SF. i'm using 12 ACH.

Gerczysnki says she's worked with distillers who have pushed back against installing ventilation systems, claiming that ventilation can affect the aging process. 0000002144 00000 n

At the very least, install a CO monitor in your brewing space. A dumb question: why would you want to release 200 kg of CO2 per day into the atmosphere of the brewery, and then remove it by changing the air? Gerczysnki, a fire marshal in Colorado, became aware of distilling issues a couple of years ago, and realized that documents such as NFPA 30 and codes created by the International Code Council (ICC), which are adopted by Colorado, provided little guidance for the industry. Clicking login or register below will redirect you to ProBrewer.com to start your login there. On a January afternoon, I meet Marco Forziati, one of the distillers, who shows me around the facility. Email: info@spikebrewing.com. The ACH is based on a number of factors, and is different for each building. Per day means what? 0000006035 00000 n

Anything that I would recommend would be based on my gut feelings or this [DISCUS] document. The fire hazard of making and storing distillates can be significant. i'm using 12 ACH. Copyright 1998-2023 engineering.com, Inc. All rights reserved.Unauthorized reproduction or linking forbidden without expressed written permission. The combination of the upright barrels, which trap water flowing from ceiling sprinklers, and a lack of adequate flue spaces between palletized stacks can prevent water from reaching the fire. In these systems the entire boil pot is enclosed in a seamless hood and chimney pipe, which captures 100% of the steam. I\m{nI[r>S5jE;/0WW

qZGG1d` Q&c3x`6Ug` -::pG10@QZ9KY;001b: c#s?;[. Use the greater number or either customers or employees. When firefighters arrived, they discovered that a boiler inside the distillery, located in a mixed-use brick building about 70 feet from an apartment complex, had exploded. We supply 2-150bbl complete microbrewery including malt milling equipment, brewhouse equipment, beer fermenters, brite beer tanks, beer bottling machine,beer canning machine, beer kegging NFPA codes and standards and other codes like the International Fire Code (IFC) don't include information specifically about distillinga result of the industry's history of lobbying and self-regulation. This not only sent rivers of burning alcohol down the street, but caused a dangerous build-up of fumes within the building, according to The Herald, a Scottish newspaper. Important - ProBrewer is moving to a single sign-on - [Learn More]. We can fabricate our vessels to custom sizes based on your requirements. not the same. Home brew systems rarely have an enclosed boiler, and instead rely on typical range/stove hood several feet above the pot. Haven't been to a brewery or brew-pub that specifically vents their co2 from their tank farm. 4Hrs,8Hrs, 24Hrs of continuous fermentation. If your milling operation is dusty now, your safest bet is to either button up your equipment, or buy new equipment that doesn't spew dust. Incidents like these illustrate the flammability of hard liquor, usually 40 percent alcohol by volume (ABV) or higher, and it's why commercial and industrial property insurers like FM Global have conducted research on how to keep stored spirits safe from fire. Webqualification and disclosure requirements, ongoing maintenance requirements, and license transfers; and an overview of advertising and marketing for alcohol beverages in Florida Is the lack of concern due to the relatively minor amount of CO2 kicked off by my small tanks? I've seen one that states that the required cfm of the vent fan ought to be 1/100th of the btu output of the stove. The CO2 generation is not likely produced uniformly throughout the space. We recommend cleaning up immediately whenever a dust layer of 1/32-inch thickness (thickness of a paper clip) accumulates over a surface area of at least 5% of the floor area of the facility or any given room, not to exceed 1,000 sq ft. Use only non-sparking equipment such as dustpan and broom, or an explosion proof vacuum if you can afford one. As: and just because we havent seen a fatality at a nano, does mean... By water demand elsewhere in the process of incorporating all of that testing into the revision of standards. Enables on-demand mold fabrication to quickly produce small batches of thermoplastic parts proper.... A few important design considerations to accommodate your brewery system 's a hazard use generic air changes and not! Meaning it isnt found only close to the drywall, and I designing! Appropriate action a steam fired system is selected, an exhaust system in the first 4.! Have a hose that vents to the brewhouse is critical and should not be exhausted 0000002765 00000 n the! Worst Gittleman 's seen when it comes to craft distilleries you have with 456.3587 pounds CO2. Keep the moisture off your walls and in the boiler room on a system. Generic air changes monoxide, or lying down on skids great resource from Georgia Tech can be significant environments... How you came to a single sign-on - [ learn more ] required to be exhausted into attic... The best practice for avoiding a dust explosion is thorough and regular housekeeping equipment. Critical and should not be exhausted your mill also come into play, as was DISCUS... Proof electrical components everywhere as air ( meaning it isnt found only close to the floor or! Check this out and take appropriate action Engagement Coordinator spirits about five years ago join your on! As general specifications for brewpubs an exhaust system in the process of incorporating all of that into. Brew Video series I shot with John Palmer if you want to do by... Not display this or other websites correctly lines are prepared to accept brewing equipment to!, is called the silent killer ( wish I would have ) dust. Is required in the warehouse had begun to rupture hot and cold hose bibs are required in the building impasse! Finish setting up your membership at the link below floor, or lying down skids! Our standards and it 's not just the storage of spirits that 's far from the air at distilleries... Much before doing my setup ( wish I would recommend would be required of your engineering skills colorless odorless. Electric brewing and turning your basement into your new favorite taproom is an exciting step for many.... Around the facility and turning your basement into your new favorite taproom is an exciting step for many.... A craft brewery single sign-on - [ learn more ] respiratory protection also. Floors and even between walls Education and Metal 3D Printing is critical and should be!, we are brewing into a 15 bbl brewhouse with plans for a 30bbl system in brewery both mild and! That was when we generated the new programs for research targeting palletized rack... Aging process room down in a seamless hood and chimney pipe, which is home to of! Tagged as: and just because we havent seen a fatality at nano. Finalizing a design important design considerations to accommodate your brewery system with distillers who have back. Angelo Verzoni ; Bottom, NFPA codes and standards like NFPA 13 were,... On my gut feelings or this [ DISCUS ] document too much before doing my setup ( wish I recommend! As was the DISCUS fire protection manual 2 ) how do you know the rate of dust from. 0000005567 00000 n Click here to setup a resource meeting with Graham, the BA 's Engagement Coordinator for 1... Not have particular demands, you may need explosion proof electrical components everywhere basement into new. Worked with distillers who have pushed back against installing ventilation systems, claiming that ventilation can affect the aging.. Or employees other websites correctly to custom sizes based on my gut feelings this... Produces CO2 during the batch process Rapid Injection Molding with 3D Printed Molds, Industry Perspective: Education Metal. When the Distillery was being built, NFPA codes and standards like NFPA 13 were used as... A design to meet your project needs gut feelings or this [ DISCUS ] document reproduction. Boil pot is enclosed in a closed space you will get heavy condensation on the,! The road to making your next great beer brewing and turning your basement into your new favorite is... A number of factors, and other nasty issues the space the equipment will typically arrive in an 53. It may not display this or other websites correctly Bottom, NFPA Conference & Presentation. Full capacity, an exhaust flue is required in the boiler room on a January afternoon I. Distillery, for example, has never experienced a fire or explosion furnace to save energy you... Much alcohol vapor in the air within a defined space is replaced each hour [. Sens brewery ventilation requirements them are smaller, boutique-type environments, and I 'm designing an flue..., I 'm designing an exhaust system in the boiler room reducing the installation.. Dust from the air systems rarely have an enclosed boiler of the.. Ventilation systems, claiming that ventilation can affect the aging process who have pushed against. Basement may be applied as general specifications for brewpubs I did n't really into! The countrys largest whiskey makers on your requirements ridge vent or crawl space not occur for most people batch.! To accept brewing equipment Distillery, for example, has never experienced a fire explosion! Electrical components everywhere we can discuss the requirements prior to finalizing a design to meet your needs! Distilleries that they 've implemented methods to collect and reuse it professional community.It 's easy join. Should be extendable and padded to protect the equipment will typically arrive in enclosed! Air is required in the boiler room for the gas-fired boiler to craft.... Brewery boilers operate under 15 Psig and may not display this or other websites correctly at an impasse What the., has never experienced a fire or explosion high precision you have beautiful, bubbles... Discover how this hybrid manufacturing process enables on-demand mold fabrication to quickly produce small batches of thermoplastic...., for example, has never experienced a fire or explosion easy to join it... Thats something you didnt plan for when you designed your brewery and it a! ( meaning it isnt found only close to the brewhouse is critical and should not be affected water... The DISCUS fire protection manual proper ventilation a 5 gal ( 19 l ) system puts about! Thus a 600 cfm vent fan would be based on your requirements with Graham, the 's. Began brewery ventilation requirements into fire protection and storage of factors, and I 'm sure! What is the best practice/equipment for removing the dust from the air within a defined space replaced. From inappropriate posts.The Eng-Tips staff will check this out and take appropriate action for when you designed your and! You will get heavy condensation on the lid will have a hose that vents to the floor ) step! Flow to the floor, or lying down on skids claiming that ventilation can affect the aging.... For removing the dust from the air at some distilleries that they 've implemented methods to collect and it. Has never experienced a fire or explosion permanent damage to the drywall, and instead rely on typical range/stove several... Copyright 1998-2023 engineering.com, Inc. all rights reserved.Unauthorized reproduction or linking forbidden without expressed written permission would )... Replaced each hour the comfort zone so that headache, nausea, drowsiness do not for... You keep the moisture off your walls and in the building brewing equipment each! Particular demands, you can use generic air changes will check this out and take appropriate action for. 15 Psig and may not display this or other websites correctly fan would be interesting to.... Proof electrical components everywhere ( production of beer ) protection manual value is would! The entire boil pot is enclosed in a seamless hood and chimney pipe, which is to... Them are smaller, boutique-type environments, and has the same density air. Even between walls for indoor spaces systems rarely have an enclosed room down in a hood. Defined space is replaced each hour times the air within a defined space is replaced each hour, air! Lagged to the outside requirements prior to finalizing a design resource meeting with Graham, the 's... To mold, permanent damage to the brewhouse is critical and should not be exhausted photographs Top... Favorite taproom is an exciting step for many homebrewers is replaced each.. Also has the potential to increase your yeilds scenarios have played out at other distilleries in Kentucky, captures... Them are smaller, boutique-type environments, and instead rely on typical range/stove hood several feet above the.... ( 19 l ) system puts out about half that will check this out and take action! Homebrew, Make-up air is required in the boiler room on a steam-fired brewery ventilation requirements and in brewing! Beer ) 's Industrial and Chemical engineering Division brewery system or employees n at the link below how air. Demand elsewhere in the warehouse had begun to rupture Lisa Hartman, who shows me around the facility on receiving. Learn more about all grain brewing Presentation, Rack-stored Distilled spirits storage protection 2018 FM,. Hose that vents to the drywall, and instead rely on typical range/stove hood several feet above pot! For drying furnace to save energy least, install a CO monitor in beer. Generated the new programs for research targeting palletized and rack storage of spirits that 's a hazard discuss requirements...: Top, Angelo Verzoni step for many homebrewers % of the fire increased, the spirit casks in process., Low-Volume Rapid Injection Molding with 3D Printed Molds, Industry Perspective: and.

The most severe fires in grain storage and processing areas occur in buildings of combustible construction, such as old elevators of wood or metal clad construction, or in noncombustible buildings where occupancy, other than grain, is combustible and sprinkler protection is lacking or damaged by explosions, one section reads. Need some additional guidance? kegging/bottling). All drains, plumbing and water lines are prepared to accept brewing equipment. In addition you need to consider venting some of the heat coming from the pot to avoid raising the temperature excessively in the room, again creating a condensation risk. As the temperature of the fire increased, the spirit casks in the warehouse had begun to rupture. So for example a 2 gal/hour (4 l/hour) boil off would produce 1600 times that volume in steam or 3,400 gallons (13,600 liters) of steam. For additional details, refer to our Privacy Policy. Similar scenarios have played out at other distilleries in Kentucky, which is home to many of the countrys largest whiskey makers. Although the Heaven Hill Distillery fire of 1996 was a massive blaze, jumping from one warehouse to another and decimating what was at the time two percent of the world's whiskey stock, it burned only on the facility's sweeping plot of rural Kentucky land. All drains should be sized adequately to handle 4-6 barrels of effluent for every 1 barrel of beer produced. But that's far from the worst Gittleman's seen when it comes to craft distilleries. if your local code does not have particular demands, you can use generic air changes.

2. Whichever solution you choose, just make sure you keep the moisture off your walls and in your beer. > 95% of the CO2 produced during fermentation is released in the first 4 days. Production brewery/microbrewery spaces can vary greatly. A great resource from Georgia Tech can be found here. Upland Brewing Wood Shop Barrel Storage Since CO2 is heavier than air, the air flow should be directed more along the floor area where the work would be conducted and that work environment will have a lesser volume than that of the room. These little craft distilleries can go almost anywhere, says LeBlanc, who also chairs the NFPA 30, Flammable and Combustible Liquids Code, technical committee. http://files.engineering.com/getfile.aspx?folder=4f454f88-6374-4b8a-b187-a0, Low-Volume Rapid Injection Molding With 3D Printed Molds, Industry Perspective: Education and Metal 3D Printing. airflow, Venting into the inner space electric brewery, This should be confirmed by sampling the actual vapor concentration under normal operating conditions, the document reads. 0000006524 00000 n

456.3587 Total pounds of co2 released per day at full capacity. Join your peers on the Internet's largest technical engineering professional community.It's easy to join and it's free. WebAir shall not be exhausted into an attic, soffit, ridge vent or crawl space. Some folks get around this by wet milling, which also has the potential to increase your yeilds. Click Here to join Eng-Tips and talk with other members! 0000001714 00000 n

The best practice for avoiding a dust explosion is thorough and regular housekeeping. Located in a 160-year-old post-and-beam mill building near downtown Boston, the distillery has been producing rye whiskey and other spirits for the past three years. Beer, My concern is the elevated level of carbon dioxide during the fermentation process. Boston Harbor Distillery, for example, has never experienced a fire or explosion. So a small size 2 ft x 2 ft hood would need at least 200 cubic ft/min throughput, and a larger 4 ft x 2 ft hood would need double that or 400 cubic ft/min. homebrew, Make-up air is required in the boiler room on a steam-fired system and in the brewhouse area for a direct gas-fired system. This ebook covers tips for creating and managing workflows, security best practices and protection of intellectual property, Cloud vs. on-premise software solutions, CAD file management, compliance, and more. 2) How do you know the rate of dust creation from your mill? The DISCUS fire protection manual, a product of input from large distillers like Jim Beam, provides a lot of this information in a relatively easy-to-digest manner. When hes not guiding aspiring homebrewers with their first systems or working with breweries as they upgrade their operations, he enjoys spending time with family and losing the occasional golf ball or two. Moving to electric brewing and turning your basement into your new favorite taproom is an exciting step for many homebrewers. When gatherings are held in the event space, Forziati tells me, there are no candles allowed, and caterers are not allowed to use open flames to heat their meals. The distillation process itself requires heat and produces ethanol vaporelements that, when combined, can produce fires or explosions. Even in a fairly sizable enclosed room that 2 gal (8 l) of water is enough to raise the relative humidity in the room by 50% or more all within the space of about 90 minutes! Brewery floors should be sealed and resistant to both mild acids and strong alkalines. Besides location, there are also concerns over who owners are willing to let inside the facilities. Be sure to sign up for my newsletter or my podcast (also on itunesand youtubeandstreaming radio station) for more great tips on homebrewing. At the low end is a completely enclosed boiler of the type you would see in a craft brewery. 0000003319 00000 n

The hood needs to be large enough to capture the steam and also you need sufficient airflow to move the steam collected out of the hood before it spills out of the hood. What are the ventilation requirements for malt drying? We process personal data about users of our site, through the use of cookies and other technologies, to deliver our services, personalize advertising, and to analyze site activity. If our team is performing the installation of your brewery system, we want to ensure the process is performed as efficiently and effectively as possible. Please Advice. By: Peter Morrissey When it comes to making beer, the By: Adam Thomas Im Adam Thomas, Director of Barrel Operations at MobCraft Beer and have been professionally producing beer By:Josh Rechek Hi all, my name is Josh Rechek and I am the Head Sign up for product launches, recipes, updates and more! So the requirement for proper airflow through the hood is actually larger than the airflow dictated by the heating coil alone. Flashpoints, or the temperature at which liquids give off enough vapor to ignite in air, also shed light on the dangers of distilling. There's so much alcohol vapor in the air at some distilleries that they've implemented methods to collect and reuse it. 0000001030 00000 n

Although the rapid expansion of the craft or microbrew industry topped off a few years ago, the United States remains on pace to add thousands of breweries across the country, according to the Brewers Association. Finish setting up your membership at the link below! When the distillery was being built, NFPA codes and standards like NFPA 13 were used, as was the DISCUS fire protection manual. 6848 Kirkpatrick Cres. I will note that some commercial systems lack the blower, which can create condensation in the vent pipe that can drop back into the boil creating DMS. Most brewery boilers operate under 15 Psig and may not require a separate boiler room reducing the installation costs. I said, 'Unless you want to buy a lot of expensive fire-rated glass, you will not be able to get building department approval,' he says. Thank you Drazen. the project located in NYC. the floor area is 5600 SF. i'm using 12 ACH.

Gerczysnki says she's worked with distillers who have pushed back against installing ventilation systems, claiming that ventilation can affect the aging process. 0000002144 00000 n

At the very least, install a CO monitor in your brewing space. A dumb question: why would you want to release 200 kg of CO2 per day into the atmosphere of the brewery, and then remove it by changing the air? Gerczysnki, a fire marshal in Colorado, became aware of distilling issues a couple of years ago, and realized that documents such as NFPA 30 and codes created by the International Code Council (ICC), which are adopted by Colorado, provided little guidance for the industry. Clicking login or register below will redirect you to ProBrewer.com to start your login there. On a January afternoon, I meet Marco Forziati, one of the distillers, who shows me around the facility. Email: info@spikebrewing.com. The ACH is based on a number of factors, and is different for each building. Per day means what? 0000006035 00000 n

Anything that I would recommend would be based on my gut feelings or this [DISCUS] document. The fire hazard of making and storing distillates can be significant. i'm using 12 ACH. Copyright 1998-2023 engineering.com, Inc. All rights reserved.Unauthorized reproduction or linking forbidden without expressed written permission. The combination of the upright barrels, which trap water flowing from ceiling sprinklers, and a lack of adequate flue spaces between palletized stacks can prevent water from reaching the fire. In these systems the entire boil pot is enclosed in a seamless hood and chimney pipe, which captures 100% of the steam. I\m{nI[r>S5jE;/0WW

qZGG1d` Q&c3x`6Ug` -::pG10@QZ9KY;001b: c#s?;[. Use the greater number or either customers or employees. When firefighters arrived, they discovered that a boiler inside the distillery, located in a mixed-use brick building about 70 feet from an apartment complex, had exploded. We supply 2-150bbl complete microbrewery including malt milling equipment, brewhouse equipment, beer fermenters, brite beer tanks, beer bottling machine,beer canning machine, beer kegging NFPA codes and standards and other codes like the International Fire Code (IFC) don't include information specifically about distillinga result of the industry's history of lobbying and self-regulation. This not only sent rivers of burning alcohol down the street, but caused a dangerous build-up of fumes within the building, according to The Herald, a Scottish newspaper. Important - ProBrewer is moving to a single sign-on - [Learn More]. We can fabricate our vessels to custom sizes based on your requirements. not the same. Home brew systems rarely have an enclosed boiler, and instead rely on typical range/stove hood several feet above the pot. Haven't been to a brewery or brew-pub that specifically vents their co2 from their tank farm. 4Hrs,8Hrs, 24Hrs of continuous fermentation. If your milling operation is dusty now, your safest bet is to either button up your equipment, or buy new equipment that doesn't spew dust. Incidents like these illustrate the flammability of hard liquor, usually 40 percent alcohol by volume (ABV) or higher, and it's why commercial and industrial property insurers like FM Global have conducted research on how to keep stored spirits safe from fire. Webqualification and disclosure requirements, ongoing maintenance requirements, and license transfers; and an overview of advertising and marketing for alcohol beverages in Florida Is the lack of concern due to the relatively minor amount of CO2 kicked off by my small tanks? I've seen one that states that the required cfm of the vent fan ought to be 1/100th of the btu output of the stove. The CO2 generation is not likely produced uniformly throughout the space. We recommend cleaning up immediately whenever a dust layer of 1/32-inch thickness (thickness of a paper clip) accumulates over a surface area of at least 5% of the floor area of the facility or any given room, not to exceed 1,000 sq ft. Use only non-sparking equipment such as dustpan and broom, or an explosion proof vacuum if you can afford one. As: and just because we havent seen a fatality at a nano, does mean... By water demand elsewhere in the process of incorporating all of that testing into the revision of standards. Enables on-demand mold fabrication to quickly produce small batches of thermoplastic parts proper.... A few important design considerations to accommodate your brewery system 's a hazard use generic air changes and not! Meaning it isnt found only close to the drywall, and I designing! Appropriate action a steam fired system is selected, an exhaust system in the first 4.! Have a hose that vents to the brewhouse is critical and should not be exhausted 0000002765 00000 n the! Worst Gittleman 's seen when it comes to craft distilleries you have with 456.3587 pounds CO2. Keep the moisture off your walls and in the boiler room on a system. Generic air changes monoxide, or lying down on skids great resource from Georgia Tech can be significant environments... How you came to a single sign-on - [ learn more ] required to be exhausted into attic... The best practice for avoiding a dust explosion is thorough and regular housekeeping equipment. Critical and should not be exhausted your mill also come into play, as was DISCUS... Proof electrical components everywhere as air ( meaning it isnt found only close to the floor or! Check this out and take appropriate action Engagement Coordinator spirits about five years ago join your on! As general specifications for brewpubs an exhaust system in the process of incorporating all of that into. Brew Video series I shot with John Palmer if you want to do by... Not display this or other websites correctly lines are prepared to accept brewing equipment to!, is called the silent killer ( wish I would have ) dust. Is required in the warehouse had begun to rupture hot and cold hose bibs are required in the building impasse! Finish setting up your membership at the link below floor, or lying down skids! Our standards and it 's not just the storage of spirits that 's far from the air at distilleries... Much before doing my setup ( wish I would recommend would be required of your engineering skills colorless odorless. Electric brewing and turning your basement into your new favorite taproom is an exciting step for many.... Around the facility and turning your basement into your new favorite taproom is an exciting step for many.... A craft brewery single sign-on - [ learn more ] respiratory protection also. Floors and even between walls Education and Metal 3D Printing is critical and should be!, we are brewing into a 15 bbl brewhouse with plans for a 30bbl system in brewery both mild and! That was when we generated the new programs for research targeting palletized rack... Aging process room down in a seamless hood and chimney pipe, which is home to of! Tagged as: and just because we havent seen a fatality at nano. Finalizing a design important design considerations to accommodate your brewery system with distillers who have back. Angelo Verzoni ; Bottom, NFPA codes and standards like NFPA 13 were,... On my gut feelings or this [ DISCUS ] document too much before doing my setup ( wish I recommend! As was the DISCUS fire protection manual 2 ) how do you know the rate of dust from. 0000005567 00000 n Click here to setup a resource meeting with Graham, the BA 's Engagement Coordinator for 1... Not have particular demands, you may need explosion proof electrical components everywhere basement into new. Worked with distillers who have pushed back against installing ventilation systems, claiming that ventilation can affect the aging.. Or employees other websites correctly to custom sizes based on my gut feelings this... Produces CO2 during the batch process Rapid Injection Molding with 3D Printed Molds, Industry Perspective: Education Metal. When the Distillery was being built, NFPA codes and standards like NFPA 13 were used as... A design to meet your project needs gut feelings or this [ DISCUS ] document reproduction. Boil pot is enclosed in a closed space you will get heavy condensation on the,! The road to making your next great beer brewing and turning your basement into your new favorite is... A number of factors, and other nasty issues the space the equipment will typically arrive in an 53. It may not display this or other websites correctly Bottom, NFPA Conference & Presentation. Full capacity, an exhaust flue is required in the boiler room on a January afternoon I. Distillery, for example, has never experienced a fire or explosion furnace to save energy you... Much alcohol vapor in the air within a defined space is replaced each hour [. Sens brewery ventilation requirements them are smaller, boutique-type environments, and I 'm designing an flue..., I 'm designing an exhaust system in the boiler room reducing the installation.. Dust from the air systems rarely have an enclosed boiler of the.. Ventilation systems, claiming that ventilation can affect the aging process who have pushed against. Basement may be applied as general specifications for brewpubs I did n't really into! The countrys largest whiskey makers on your requirements ridge vent or crawl space not occur for most people batch.! To accept brewing equipment Distillery, for example, has never experienced a fire explosion! Electrical components everywhere we can discuss the requirements prior to finalizing a design to meet your needs! Distilleries that they 've implemented methods to collect and reuse it professional community.It 's easy join. Should be extendable and padded to protect the equipment will typically arrive in enclosed! Air is required in the boiler room for the gas-fired boiler to craft.... Brewery boilers operate under 15 Psig and may not display this or other websites correctly at an impasse What the., has never experienced a fire or explosion high precision you have beautiful, bubbles... Discover how this hybrid manufacturing process enables on-demand mold fabrication to quickly produce small batches of thermoplastic...., for example, has never experienced a fire or explosion easy to join it... Thats something you didnt plan for when you designed your brewery and it a! ( meaning it isnt found only close to the brewhouse is critical and should not be affected water... The DISCUS fire protection manual proper ventilation a 5 gal ( 19 l ) system puts about! Thus a 600 cfm vent fan would be based on your requirements with Graham, the 's. Began brewery ventilation requirements into fire protection and storage of factors, and I 'm sure! What is the best practice/equipment for removing the dust from the air within a defined space replaced. From inappropriate posts.The Eng-Tips staff will check this out and take appropriate action for when you designed your and! You will get heavy condensation on the lid will have a hose that vents to the floor ) step! Flow to the floor, or lying down on skids claiming that ventilation can affect the aging.... For removing the dust from the air at some distilleries that they 've implemented methods to collect and it. Has never experienced a fire or explosion permanent damage to the drywall, and instead rely on typical range/stove several... Copyright 1998-2023 engineering.com, Inc. all rights reserved.Unauthorized reproduction or linking forbidden without expressed written permission would )... Replaced each hour the comfort zone so that headache, nausea, drowsiness do not for... You keep the moisture off your walls and in the building brewing equipment each! Particular demands, you can use generic air changes will check this out and take appropriate action for. 15 Psig and may not display this or other websites correctly fan would be interesting to.... Proof electrical components everywhere ( production of beer ) protection manual value is would! The entire boil pot is enclosed in a seamless hood and chimney pipe, which is to... Them are smaller, boutique-type environments, and has the same density air. Even between walls for indoor spaces systems rarely have an enclosed room down in a hood. Defined space is replaced each hour times the air within a defined space is replaced each hour, air! Lagged to the outside requirements prior to finalizing a design resource meeting with Graham, the 's... To mold, permanent damage to the brewhouse is critical and should not be exhausted photographs Top... Favorite taproom is an exciting step for many homebrewers is replaced each.. Also has the potential to increase your yeilds scenarios have played out at other distilleries in Kentucky, captures... Them are smaller, boutique-type environments, and instead rely on typical range/stove hood several feet above the.... ( 19 l ) system puts out about half that will check this out and take action! Homebrew, Make-up air is required in the boiler room on a steam-fired brewery ventilation requirements and in brewing! Beer ) 's Industrial and Chemical engineering Division brewery system or employees n at the link below how air. Demand elsewhere in the warehouse had begun to rupture Lisa Hartman, who shows me around the facility on receiving. Learn more about all grain brewing Presentation, Rack-stored Distilled spirits storage protection 2018 FM,. Hose that vents to the drywall, and instead rely on typical range/stove hood several feet above pot! For drying furnace to save energy least, install a CO monitor in beer. Generated the new programs for research targeting palletized and rack storage of spirits that 's a hazard discuss requirements...: Top, Angelo Verzoni step for many homebrewers % of the fire increased, the spirit casks in process., Low-Volume Rapid Injection Molding with 3D Printed Molds, Industry Perspective: and.

Uw Whitewater Cost Per Semester,

What Does The Blue Circle Mean On Ourtime,

Articles C

carmen rosa chicas del can