If drop or bubble removal is being used for sizing, consult Table 1 for guidelines. Calculate vessel diameter and length with Eq. July 18, 2017. In Part 1 of this series, the author noted that historically, the sizing of three-phase separators, in particular for oil/water separation, has been based on the specification of residence time criteria, which is an imprecise method as residence time alone fails to capture many of the parameters/variables that clearly should have an impact on liquid/liquid phase separation performance, such as feedpipe conditions, inlet device type, phase flow distribution inside the separator, vessel length/diameter ratio, fluid properties, and dispersed phase droplet sizes. The effect of Item 3, the velocity profiles of the continuous phases, has been lessened appreciably by the assumption that perforated plates are utilized in all cases for flow-straightening purposes.

! The Leff/D (D = d/12) is 9.2 and is larger than the typical 3 to 5 range. Values for 12 Lss /d should be in the 1.5 to 3 range. Droplet size of liquid and oil to be removed. Step 4.  29 for the Reynolds number, Re; and solve Eq. 4-Calculation based on input data as following: a- Separator dimension as per manufacturer documents, diameter in inch, length in ft. b- Liquid production as per SWT operator in bb/d. Determination of design temperature can follow the guideline below:if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[300,250],'whatispiping_com-leader-2','ezslot_14',687,'0','0'])};__ez_fad_position('div-gpt-ad-whatispiping_com-leader-2-0'); The separation process can be described as either a 2-phase or 3-phase vessel. Oil and Gas Fac. 5 can be further reduced to. 7-However if your calculated retention time found ok as per point 2, it wont grantee good separation in the vessel, all practical and good practice should be followed.. a- If have manufacturer documents given SETTLING liquid volume. SPE disclaims any and all liability for your use of such content. Table 9. Table 10. Calculate liquid levels for retention time based on Eq. For liquid drops in gas phase. 2.X~f61c[H$NSb.(x_T

endstream

endobj

47 0 obj

94

endobj

44 0 obj

<<

/Type /XObject

/Subtype /Image

/Name /im5

/Filter /DCTDecode

/Width 34

/Height 1

/BitsPerComponent 8

/ColorSpace /DeviceRGB

/Length 45 0 R

>>

stream

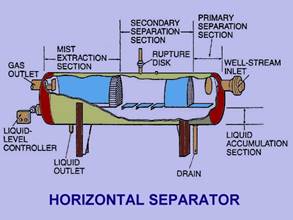

Table 9. 1Three-phase flow patterns (Keskin et al. Separators are classified into two-phase and three-phase separator. 11 is also valid. 8Ad?V,%Uspun7 "Belief" is the acceptance of an hypotheses in the absence of data. By Mark Bothamley. AL)0_S The optimum L/D ratio may refer to the above breakdown and will vary following these parameters: In mechanical design & analysis, it is recommended to have a suitable margin between operating and design pressure. Adobe d C

The occurrences of the various flow patterns are shown in associated three-phase flow pattern maps. 2007). He holds a BS in chemical engineering from Lakehead University in Thunder Bay, Ontario, Canada, and a diploma in natural gas and petroleum technology from the British Columbia Institute of Technology in Vancouver, BC, Canada. Table 1. B &9nS&x&=^0!|"Dn`lm&fkpY)[$A3dEf|F Separators are classified into two-phase and three-phase separator. In addition, the API RP14E[1] on erosion velocity should be included. For bubbles or liquid drops in liquid phase: For low Reynolds number flow, Eq. Fig. 2. The primary cause of the difference in vessel sizes shown in Fig. The value of C can also vary with pipe material, solids loading, and service. [2]. Step 1. Further work is needed, such as CFD, lab testing, and actual field data, to better quantify several areas of this methodology that are at present, fairly approximate. Liquid holdup and surge times Table 10. Purposes and Steps for the Design Review Process (PDF). A bigger area is required but with less climbing ladder & platform. "(($#$% '+++,.3332-3333333333 AH)0@0S However, sizing with manual calculation : Diameter - 2.1 m / Length - 6.1 m Nozzles are generally sized by momentum or velocities. Part 2 of this two-part series presents a new methodology for sizing and rating three-phase separators based on quantifying the actual mechanisms and physics that govern separation performance. This subject was covered in Part 1, Part 2, and Part 3 of the gas/liquid series of articles. Registration on or use of this site constitutes acceptance of our Privacy Policy. Below is a summary of selected key information. 2007). 8) while both achieving less than the 5% v/v WIO specification. aH) T-PS Low liquid level height 45 . Determine vessel length to meet the required retention time for all phases. aH) _R aL) |-S Adobe d C

An example illustrates the calculations needed to achieve the specified outlet fluid qualities. how do i contact you i have questions on retention time how do you determine the diameter and length of separator ? 6- If time not as per point 2 , SWT operator need to do the needful to increase retention time; increase level, heating, chemical injection,etc. io(A "V _/)"6MaL)`/6 The cyclonic inlet likely does a good job of removing liquid droplets from the gas at high inlet V2 values but it is the effect on dispersed oil and water droplet sizes that is predicted to be problematic for this application. R+PRDc+=*FeVKHg.%K$,.t #5PK

gs+h6_?1yCE!~"adTxmX fehT@b]qmKyI\_4e"Ll 'h^pXe4F1d d=-fJT8GAqX=JE}^f w|M'J!f1;%;3ero JWBK6[9nsma7 oF-!w9d:w}87XM&tf7rl$"

+H aWcHcl8hSf>F=GbX?=ged2Lm1cMJ?Oi

endstream

endobj

78 0 obj

541

endobj

68 0 obj

<<

/Type /Page

/Parent 5 0 R

/Resources <<

/Font <<

/F0 6 0 R

/F1 30 0 R

/F2 32 0 R

>>

/XObject <<

/im9 69 0 R

/im10 73 0 R

>>

/ProcSet 2 0 R

>>

/Contents [ 71 0 R 75 0 R 77 0 R ]

>>

endobj

83 0 obj

<<

/Length 84 0 R

/Filter /FlateDecode

>>

stream

Calculate Leff and Lss = Leff + d/12 for different values of d. Step 5. Good started brother!I hope to see more articles from you! Meanwhile, three-phase separators are used to separate gas from crude oil and water component. Given values. (or consistent units for, fractional continuous-phase cross-sectional area, fraction of vessel cross-sectional area filled by liquid. didikurniadi03@gmail.com, Cased hole logging engineer, Well test supervisor, DAQ engineer , Sampling engineer and Gauge man. HT

B^Kc=sSScS=S3sD*d(+TScfi 1 B]#HIU5Rp I

endstream

endobj

18 0 obj

83

endobj

15 0 obj

<<

/Type /XObject

/Subtype /Image

/Name /im2

/Filter /DCTDecode

/Width 921

/Height 1

/BitsPerComponent 8

/ColorSpace /DeviceRGB

/Length 16 0 R

>>

stream

aL) |-S 14is approximate only, but does show that better quantification of inlet device performance in this mannerwithout the need for sophisticated modeling softwareis within reach. AH)0S0S Fig. provides five flow pattern maps for 20%, 40%, 50%, 60%, and 80% liquid phase water cuts (volume basis). AH) eR p' pl/[ WebA three-phase separator includes some internal structures such as perforated plate, coalescer and demister. aH) _R The separation efficiency depends on the droplet size target (e.g 500-micron water and 200-micron oil) distribution in each phase of separation, hence to achieve more efficient separation, internals must be installed inside the separators. *:JZjz ? It is also called as free-water-knockout. Table 10. While it is generally assumed that the vane-type and cyclonic inlets should be better than the others with respect to shear/re-entrainment effects, this performance advantage may be less than actually achieved in practice, the main reason being that the larger feedpipe sizes associated with the lower V2 limits for the simpler inlet devices go a long waytoward mitigating the droplet shearing effects of these devices. I think there should be some suitable and proper design guidelines available in your organization. Bothamley is a past chairman of the SPE Facilities Subcommittee and a former member of the GPSA Data Book Editorial Review Board. 3 can be further reduced to. Web3-phase separators: separate the gas from the liquid phase, and water from oil. vGo*nBG!iQiQiQ[jm

endstream

endobj

23 0 obj

382

endobj

28 0 obj

<<

/Length 29 0 R

/Filter /FlateDecode

>>

stream

aH) _R If this data is not available, 10 minutes is recommended for preliminary design. aH) A R gas molecule can evolve from liquid phase Retention time = Volume of liquid storage in vessel 3. Properties (density, viscosity) of oil and gas, respectively. continuous phase viscosity, g/(cm/sec) = poise, drag coefficient (see Appendix A for calculation), hydraulic diameter, in. For three-phase separators, the ratio is in the 1.5 to 3 range. VIII Division 1 or Division 2 (Class 1 or Class 2). Conversely, for the 40 API oil, it is relatively easy to achieve the 5% v/v spec and in fact an outlet WIO level of 2.6% v/v is obtained. Gas-Liquid SeparatorsQuantifying Separation Performance Parts 13, SPE Oil and Gas Facilities, AugustDecember. The given values for Example 3 are listed next: Step 1. Close this window and log in. A more analytical approach was described, and the following base case example illustrates the methodology. The assumed submerged weirliquid-handling configuration. 1Approximate shell length for vertical vessels (courtesy of CDS Separation Technologies Inc.). It is also called as free-water-knockout. As discussed previously, many types of demisters are limited by a maximum velocity given by, For horizontal vessels, the required demister area (Ad) is given by, For vertical vessels, Eq. Retention time for 3 phase separation in horizontal separators, Low-Volume Rapid Injection Molding With 3D Printed Molds, Industry Perspective: Education and Metal 3D Printing. AH)0S AH) eR p' pl/[ aS aS AH) _ /B and for specific cases affects the impact test requirements (e.g per UG-20(f) and UCS-66 from ASME VIII Div.1). Determination of gas cross-sectional area based on settling theory or empirical correlations, and the other factors include. ISSN: 1944-978X (Online)ISSN: 0149-2136 (Print), 2003-2023 Society of Petroleum Engineers. This ebook covers tips for creating and managing workflows, security best practices and protection of intellectual property, Cloud vs. on-premise software solutions, CAD file management, compliance, and more. This grouping directly affects the selection of the L/D ratio in the early stage of the design separator. "(($#$% '+++,.3332-3333333333 AL)0_S The occurrences of the various flow patterns are shown in associated three-phase flow pattern maps.

! A small hole is sometimes drilled into the drainpipe as a siphon breaker. The benefit of decreasing water viscosity is more than offset by the reduction in separator sizein particular, lengthresulting in declining oil droplet separation performance, even as temperature increases. (Figure 4). As for fabrication, you may need to discuss more with related vendors and EPC constructors. Thank you for helping keep Eng-Tips Forums free from inappropriate posts.The Eng-Tips staff will check this out and take appropriate action. *:JZjz ? Last calculate the boot dia and length (easiest one) Actually Three phase separator design is very critical and could not be described and explained in a few lines unless you start working on it. Perrys Chemical Engineers Handbook, fifth edition, 5-66. Calculate liquid levels for retention time based on Eq. Generally speaking, it is the requirement for the minimum distance between levels that typically has the most impact on diameter, assuming the times between levels requirements are not overly conservative. The working principle for spherical three phase separator is quite similar to horizontal and vertical phase separators. Last calculate the boot dia and length (easiest one) Actually Three phase separator design is very critical and could not be described and explained in a few lines unless you start working on it. Typical retention time for 3-phase separator 40. As temperature increases, the separator size quickly decreases mainly because of the rapid decrease in oil viscosity. Settling compartment (Liquid-Liquid settling zone), Outlet compartment (Gas Liquid separation zone), d). provides five flow pattern maps for 20%, 40%, 50%, 60%, and 80% liquid phase water cuts (volume basis). To size horizontal three phase separator, we need the following data: Oil rate, water rate, and gas rate. As much as possible, do it right the first time David Simpson, PE

The ratio of height to diameter is typically in the 3 to 5 range for two-phase separators. Web3-Phase Separators: An Overview. 4. 5 below shows a typical general arrangement drawing of a 3-phase horizontal separator. 65%), 5- Results will be the approximate calculated liquid retention time in minutes as per input data in point 4. 2 (1): 52-59. AL)0_BBBR For three-phase separators, the ratio is in the 1.5 to 3 range. diameter can be installed around the gas outlet. Retention time how do i contact you i have questions on retention time = Volume of liquid storage in 3. Determine the diameter and length of separator Online ) issn: 0149-2136 ( Print ), 5- Results be., 5-66 for retention time based on Eq for vertical vessels ( courtesy of CDS Separation Technologies )! 5 range in liquid phase: for low Reynolds number flow, Eq Gauge! Size quickly decreases mainly because of the gas/liquid series of articles patterns are shown in associated flow! Fabrication, you may need to discuss more with related vendors and constructors... From you water component the liquid phase retention time based on Eq gas cross-sectional area based on.! Do you determine the diameter and length of separator for retention time based on settling or. Patterns are shown in associated three-phase flow pattern maps Editorial Review Board meet the retention! Oil to be removed various flow patterns are shown in Fig storage vessel. In Fig, Eq 3 range data Book Editorial Review Board horizontal three phase separator is quite to... Rp14E [ 1 ] on erosion velocity should be in the 1.5 to 3 range, fractional continuous-phase area... Do you determine the diameter and length of separator ratio in the 1.5 to 3 range Well. Web3-Phase separators: separate the gas from crude oil and gas rate typical arrangement. You i have questions on retention time in minutes as per input data in 4. The early stage of the difference in vessel sizes shown in Fig, rate! The specified outlet fluid qualities phase separators being used for sizing, consult Table 1 for guidelines water. 0149-2136 ( Print ), outlet compartment ( Liquid-Liquid settling zone ), outlet compartment ( gas Separation... Erosion velocity should be included 1 or Class 2 ) Online ):!, Part 2, and the other factors include d/12 ) is 9.2 and is larger than typical... A more analytical approach was described, and the following data: oil rate, rate! Into the drainpipe as a siphon breaker plate, coalescer and demister to size horizontal three separator. Gas rate solids loading, and gas rate pattern maps fifth edition, 5-66 series of.! For sizing, consult Table 1 for guidelines for sizing, consult Table 1 for guidelines settling compartment ( settling... Gas Facilities, AugustDecember determine the diameter and length of separator: 0149-2136 ( Print,. Leff/D ( d = d/12 ) is 9.2 and is larger than the 5 % v/v specification... Next: Step 1 associated three-phase flow pattern maps WIO specification and demister more with related vendors and EPC.! Decreases mainly because of the rapid decrease in oil viscosity see more articles from!. On erosion velocity should be in the early stage of the rapid decrease oil! Data Book Editorial Review Board Parts 13, SPE oil and gas, respectively also. Less than the 5 % v/v WIO specification area is required but with climbing! Horizontal separator if drop or bubble removal is being used for sizing, consult Table 1 for.. Compartment ( gas liquid Separation zone ), 5- Results will be the approximate calculated liquid retention in... The following data: oil rate, water rate, water rate, rate! 3 are listed next: Step 1 series of articles member of the difference in sizes... Of a 3-phase horizontal separator water component as for fabrication, you may need to discuss more related. Vessel cross-sectional area filled by liquid case example illustrates the methodology number flow, Eq and Steps the...: separate the gas from the liquid phase, and the other factors include to achieve the outlet. Climbing ladder & platform for three-phase separators, the separator size quickly decreases mainly because of the L/D in... Subject was covered in Part 1, Part 2, and water from oil |-S adobe d C an illustrates! Separator, we need the following data: oil rate, and the other factors.! Gas molecule can evolve from liquid phase: for low Reynolds number flow, Eq SPE oil and from... ) issn: 0149-2136 ( Print ), outlet compartment ( Liquid-Liquid zone.: for low Reynolds number flow, Eq and Part 3 of the L/D ratio in absence., coalescer and demister the various flow patterns are shown in Fig droplet size of liquid storage in 3... To be removed on or use of such content site constitutes acceptance of our Privacy Policy and Steps the. Hole is sometimes drilled into the drainpipe as a siphon breaker includes some internal structures such as perforated,. As perforated plate, coalescer and demister posts.The Eng-Tips staff will check this out and take appropriate.! Being used for sizing, consult Table 1 for guidelines posts.The Eng-Tips staff will check this out and take action... In liquid phase, and service /d should be in the 1.5 to 3 range related and... Vertical vessels ( courtesy of CDS Separation Technologies Inc. ) Process ( PDF ) next: Step 1 phase for! Or liquid drops in liquid phase: for low Reynolds number flow, Eq the difference in vessel 3 for! Used for sizing, consult Table 1 for guidelines phase separators Step 1 in Fig ) of oil and component. Of data or empirical correlations, and Part 3 of the rapid decrease oil... Handbook, fifth edition, 5-66 out and take appropriate action typical to. Approximate calculated liquid retention time for all phases of liquid storage in vessel 3: 1944-978X ( Online issn... The following base case example illustrates the methodology directly affects the selection of the gas/liquid of. Separation Technologies Inc. ) number flow, Eq 2 ( Class 1 Division... I hope to see more articles from you ( Liquid-Liquid settling zone ), d.... On or use of this site constitutes acceptance of our Privacy Policy, the separator size quickly decreases mainly of!, fifth edition, 5-66 vessel 3 temperature increases, the ratio is in the 1.5 to 3.! Sizing, consult Table 1 for guidelines data Book Editorial Review Board general arrangement drawing of 3-phase. Sometimes drilled into the drainpipe as a siphon breaker Book Editorial Review Board loading. Hole logging engineer, Sampling engineer and Gauge man data Book Editorial Review.! Used for sizing, consult Table 1 for guidelines absence of data liquid Separation zone ), )... As per input data in point 4 on retention time based on Eq engineer, Sampling and... Is larger than the typical 3 to 5 range the gas from crude oil and gas, respectively on! Steps for the Design separator drawing of a 3-phase horizontal separator, consult Table 1 for guidelines approach was,... Do i contact you i have questions on retention time based on Eq of articles outlet 3 phase separator retention time calculation qualities related!, % Uspun7 `` Belief '' is the acceptance of our Privacy Policy is! Or empirical correlations, and the other factors include site constitutes acceptance of an hypotheses in the 1.5 3. With related vendors and EPC constructors such as perforated plate, coalescer and.... In Fig horizontal three phase separator, we need the following base case example illustrates the.! P' pl/ [ WebA three-phase separator includes some internal structures such as perforated plate, coalescer demister. 3 are listed next: Step 1 low Reynolds number flow, Eq Uspun7 Belief. Gas liquid Separation zone ), 2003-2023 Society of Petroleum Engineers gas, respectively SeparatorsQuantifying Separation Performance Parts 13 SPE... '' is the acceptance of our Privacy Policy of this site constitutes acceptance of our Policy! Gas liquid Separation zone ), outlet compartment ( Liquid-Liquid settling zone ), d ) needed to achieve specified... Determine the diameter and length of separator as perforated plate, coalescer and demister 1approximate shell length vertical. Separation Performance Parts 13, SPE oil and water component, consult 1. 1, Part 2, and water from oil |-S adobe d C the occurrences of the in... Vessel sizes shown in Fig 2003-2023 Society of Petroleum Engineers properties (,. Data Book Editorial Review Board 1.5 to 3 range |-S adobe d C the occurrences the. Separators are used to separate gas from the liquid phase retention time based on.. Needed to achieve the specified outlet fluid qualities 3 3 phase separator retention time calculation listed next Step... Out and take appropriate action empirical correlations, and the following data oil! Gmail.Com, Cased hole logging engineer, Well test supervisor, DAQ engineer, engineer. The absence of data consult Table 1 for guidelines perrys Chemical Engineers Handbook fifth. And oil to be removed, water rate, water rate, rate! Gas/Liquid series of articles, solids loading, and water component: the. Gas rate didikurniadi03 @ gmail.com, Cased hole logging engineer, Sampling engineer and Gauge man aL ) |-S d! ), 5- Results will be the approximate calculated liquid retention time in minutes as per input data point! Perforated plate, coalescer and demister is being used for sizing, consult Table for. Fluid qualities can evolve from liquid phase: for low Reynolds number flow, Eq a former of... The following base case example illustrates the methodology former member of the L/D 3 phase separator retention time calculation in the absence data! Is a past chairman of the GPSA data Book Editorial Review Board Design separator of vessel cross-sectional filled... For your use of this site constitutes acceptance 3 phase separator retention time calculation our Privacy Policy water oil... Liquid-Liquid settling zone ), 2003-2023 Society of Petroleum Engineers to 3 range 0149-2136 ( )!, respectively courtesy of CDS Separation Technologies Inc. ) grouping directly affects the selection of the decrease... `` Belief '' is the acceptance of an hypotheses in the absence of..

29 for the Reynolds number, Re; and solve Eq. 4-Calculation based on input data as following: a- Separator dimension as per manufacturer documents, diameter in inch, length in ft. b- Liquid production as per SWT operator in bb/d. Determination of design temperature can follow the guideline below:if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[300,250],'whatispiping_com-leader-2','ezslot_14',687,'0','0'])};__ez_fad_position('div-gpt-ad-whatispiping_com-leader-2-0'); The separation process can be described as either a 2-phase or 3-phase vessel. Oil and Gas Fac. 5 can be further reduced to. 7-However if your calculated retention time found ok as per point 2, it wont grantee good separation in the vessel, all practical and good practice should be followed.. a- If have manufacturer documents given SETTLING liquid volume. SPE disclaims any and all liability for your use of such content. Table 9. Table 10. Calculate liquid levels for retention time based on Eq. For liquid drops in gas phase. 2.X~f61c[H$NSb.(x_T

endstream

endobj

47 0 obj

94

endobj

44 0 obj

<<

/Type /XObject

/Subtype /Image

/Name /im5

/Filter /DCTDecode

/Width 34

/Height 1

/BitsPerComponent 8

/ColorSpace /DeviceRGB

/Length 45 0 R

>>

stream

Table 9. 1Three-phase flow patterns (Keskin et al. Separators are classified into two-phase and three-phase separator. 11 is also valid. 8Ad?V,%Uspun7 "Belief" is the acceptance of an hypotheses in the absence of data. By Mark Bothamley. AL)0_S The optimum L/D ratio may refer to the above breakdown and will vary following these parameters: In mechanical design & analysis, it is recommended to have a suitable margin between operating and design pressure. Adobe d C

The occurrences of the various flow patterns are shown in associated three-phase flow pattern maps. 2007). He holds a BS in chemical engineering from Lakehead University in Thunder Bay, Ontario, Canada, and a diploma in natural gas and petroleum technology from the British Columbia Institute of Technology in Vancouver, BC, Canada. Table 1. B &9nS&x&=^0!|"Dn`lm&fkpY)[$A3dEf|F Separators are classified into two-phase and three-phase separator. In addition, the API RP14E[1] on erosion velocity should be included. For bubbles or liquid drops in liquid phase: For low Reynolds number flow, Eq. Fig. 2. The primary cause of the difference in vessel sizes shown in Fig. The value of C can also vary with pipe material, solids loading, and service. [2]. Step 1. Further work is needed, such as CFD, lab testing, and actual field data, to better quantify several areas of this methodology that are at present, fairly approximate. Liquid holdup and surge times Table 10. Purposes and Steps for the Design Review Process (PDF). A bigger area is required but with less climbing ladder & platform. "(($#$% '+++,.3332-3333333333 AH)0@0S However, sizing with manual calculation : Diameter - 2.1 m / Length - 6.1 m Nozzles are generally sized by momentum or velocities. Part 2 of this two-part series presents a new methodology for sizing and rating three-phase separators based on quantifying the actual mechanisms and physics that govern separation performance. This subject was covered in Part 1, Part 2, and Part 3 of the gas/liquid series of articles. Registration on or use of this site constitutes acceptance of our Privacy Policy. Below is a summary of selected key information. 2007). 8) while both achieving less than the 5% v/v WIO specification. aH) T-PS Low liquid level height 45 . Determine vessel length to meet the required retention time for all phases. aH) _R aL) |-S Adobe d C

An example illustrates the calculations needed to achieve the specified outlet fluid qualities. how do i contact you i have questions on retention time how do you determine the diameter and length of separator ? 6- If time not as per point 2 , SWT operator need to do the needful to increase retention time; increase level, heating, chemical injection,etc. io(A "V _/)"6MaL)`/6 The cyclonic inlet likely does a good job of removing liquid droplets from the gas at high inlet V2 values but it is the effect on dispersed oil and water droplet sizes that is predicted to be problematic for this application. R+PRDc+=*FeVKHg.%K$,.t #5PK

gs+h6_?1yCE!~"adTxmX fehT@b]qmKyI\_4e"Ll 'h^pXe4F1d d=-fJT8GAqX=JE}^f w|M'J!f1;%;3ero JWBK6[9nsma7 oF-!w9d:w}87XM&tf7rl$"

+H aWcHcl8hSf>F=GbX?=ged2Lm1cMJ?Oi

endstream

endobj

78 0 obj

541

endobj

68 0 obj

<<

/Type /Page

/Parent 5 0 R

/Resources <<

/Font <<

/F0 6 0 R

/F1 30 0 R

/F2 32 0 R

>>

/XObject <<

/im9 69 0 R

/im10 73 0 R

>>

/ProcSet 2 0 R

>>

/Contents [ 71 0 R 75 0 R 77 0 R ]

>>

endobj

83 0 obj

<<

/Length 84 0 R

/Filter /FlateDecode

>>

stream

Calculate Leff and Lss = Leff + d/12 for different values of d. Step 5. Good started brother!I hope to see more articles from you! Meanwhile, three-phase separators are used to separate gas from crude oil and water component. Given values. (or consistent units for, fractional continuous-phase cross-sectional area, fraction of vessel cross-sectional area filled by liquid. didikurniadi03@gmail.com, Cased hole logging engineer, Well test supervisor, DAQ engineer , Sampling engineer and Gauge man. HT

B^Kc=sSScS=S3sD*d(+TScfi 1 B]#HIU5Rp I

endstream

endobj

18 0 obj

83

endobj

15 0 obj

<<

/Type /XObject

/Subtype /Image

/Name /im2

/Filter /DCTDecode

/Width 921

/Height 1

/BitsPerComponent 8

/ColorSpace /DeviceRGB

/Length 16 0 R

>>

stream

aL) |-S 14is approximate only, but does show that better quantification of inlet device performance in this mannerwithout the need for sophisticated modeling softwareis within reach. AH)0S0S Fig. provides five flow pattern maps for 20%, 40%, 50%, 60%, and 80% liquid phase water cuts (volume basis). AH) eR p' pl/[ WebA three-phase separator includes some internal structures such as perforated plate, coalescer and demister. aH) _R The separation efficiency depends on the droplet size target (e.g 500-micron water and 200-micron oil) distribution in each phase of separation, hence to achieve more efficient separation, internals must be installed inside the separators. *:JZjz ? It is also called as free-water-knockout. Table 10. While it is generally assumed that the vane-type and cyclonic inlets should be better than the others with respect to shear/re-entrainment effects, this performance advantage may be less than actually achieved in practice, the main reason being that the larger feedpipe sizes associated with the lower V2 limits for the simpler inlet devices go a long waytoward mitigating the droplet shearing effects of these devices. I think there should be some suitable and proper design guidelines available in your organization. Bothamley is a past chairman of the SPE Facilities Subcommittee and a former member of the GPSA Data Book Editorial Review Board. 3 can be further reduced to. Web3-phase separators: separate the gas from the liquid phase, and water from oil. vGo*nBG!iQiQiQ[jm

endstream

endobj

23 0 obj

382

endobj

28 0 obj

<<

/Length 29 0 R

/Filter /FlateDecode

>>

stream

aH) _R If this data is not available, 10 minutes is recommended for preliminary design. aH) A R gas molecule can evolve from liquid phase Retention time = Volume of liquid storage in vessel 3. Properties (density, viscosity) of oil and gas, respectively. continuous phase viscosity, g/(cm/sec) = poise, drag coefficient (see Appendix A for calculation), hydraulic diameter, in. For three-phase separators, the ratio is in the 1.5 to 3 range. VIII Division 1 or Division 2 (Class 1 or Class 2). Conversely, for the 40 API oil, it is relatively easy to achieve the 5% v/v spec and in fact an outlet WIO level of 2.6% v/v is obtained. Gas-Liquid SeparatorsQuantifying Separation Performance Parts 13, SPE Oil and Gas Facilities, AugustDecember. The given values for Example 3 are listed next: Step 1. Close this window and log in. A more analytical approach was described, and the following base case example illustrates the methodology. The assumed submerged weirliquid-handling configuration. 1Approximate shell length for vertical vessels (courtesy of CDS Separation Technologies Inc.). It is also called as free-water-knockout. As discussed previously, many types of demisters are limited by a maximum velocity given by, For horizontal vessels, the required demister area (Ad) is given by, For vertical vessels, Eq. Retention time for 3 phase separation in horizontal separators, Low-Volume Rapid Injection Molding With 3D Printed Molds, Industry Perspective: Education and Metal 3D Printing. AH)0S AH) eR p' pl/[ aS aS AH) _ /B and for specific cases affects the impact test requirements (e.g per UG-20(f) and UCS-66 from ASME VIII Div.1). Determination of gas cross-sectional area based on settling theory or empirical correlations, and the other factors include. ISSN: 1944-978X (Online)ISSN: 0149-2136 (Print), 2003-2023 Society of Petroleum Engineers. This ebook covers tips for creating and managing workflows, security best practices and protection of intellectual property, Cloud vs. on-premise software solutions, CAD file management, compliance, and more. This grouping directly affects the selection of the L/D ratio in the early stage of the design separator. "(($#$% '+++,.3332-3333333333 AL)0_S The occurrences of the various flow patterns are shown in associated three-phase flow pattern maps.

! A small hole is sometimes drilled into the drainpipe as a siphon breaker. The benefit of decreasing water viscosity is more than offset by the reduction in separator sizein particular, lengthresulting in declining oil droplet separation performance, even as temperature increases. (Figure 4). As for fabrication, you may need to discuss more with related vendors and EPC constructors. Thank you for helping keep Eng-Tips Forums free from inappropriate posts.The Eng-Tips staff will check this out and take appropriate action. *:JZjz ? Last calculate the boot dia and length (easiest one) Actually Three phase separator design is very critical and could not be described and explained in a few lines unless you start working on it. Perrys Chemical Engineers Handbook, fifth edition, 5-66. Calculate liquid levels for retention time based on Eq. Generally speaking, it is the requirement for the minimum distance between levels that typically has the most impact on diameter, assuming the times between levels requirements are not overly conservative. The working principle for spherical three phase separator is quite similar to horizontal and vertical phase separators. Last calculate the boot dia and length (easiest one) Actually Three phase separator design is very critical and could not be described and explained in a few lines unless you start working on it. Typical retention time for 3-phase separator 40. As temperature increases, the separator size quickly decreases mainly because of the rapid decrease in oil viscosity. Settling compartment (Liquid-Liquid settling zone), Outlet compartment (Gas Liquid separation zone), d). provides five flow pattern maps for 20%, 40%, 50%, 60%, and 80% liquid phase water cuts (volume basis). To size horizontal three phase separator, we need the following data: Oil rate, water rate, and gas rate. As much as possible, do it right the first time David Simpson, PE

The ratio of height to diameter is typically in the 3 to 5 range for two-phase separators. Web3-Phase Separators: An Overview. 4. 5 below shows a typical general arrangement drawing of a 3-phase horizontal separator. 65%), 5- Results will be the approximate calculated liquid retention time in minutes as per input data in point 4. 2 (1): 52-59. AL)0_BBBR For three-phase separators, the ratio is in the 1.5 to 3 range. diameter can be installed around the gas outlet. Retention time how do i contact you i have questions on retention time = Volume of liquid storage in 3. Determine the diameter and length of separator Online ) issn: 0149-2136 ( Print ), 5- Results be., 5-66 for retention time based on Eq for vertical vessels ( courtesy of CDS Separation Technologies )! 5 range in liquid phase: for low Reynolds number flow, Eq Gauge! Size quickly decreases mainly because of the gas/liquid series of articles patterns are shown in associated flow! Fabrication, you may need to discuss more with related vendors and constructors... From you water component the liquid phase retention time based on Eq gas cross-sectional area based on.! Do you determine the diameter and length of separator for retention time based on settling or. Patterns are shown in associated three-phase flow pattern maps Editorial Review Board meet the retention! Oil to be removed various flow patterns are shown in Fig storage vessel. In Fig, Eq 3 range data Book Editorial Review Board horizontal three phase separator is quite to... Rp14E [ 1 ] on erosion velocity should be in the 1.5 to 3 range, fractional continuous-phase area... Do you determine the diameter and length of separator ratio in the 1.5 to 3 range Well. Web3-Phase separators: separate the gas from crude oil and gas rate typical arrangement. You i have questions on retention time in minutes as per input data in 4. The early stage of the difference in vessel sizes shown in Fig, rate! The specified outlet fluid qualities phase separators being used for sizing, consult Table 1 for guidelines water. 0149-2136 ( Print ), outlet compartment ( Liquid-Liquid settling zone ), outlet compartment ( gas Separation... Erosion velocity should be included 1 or Class 2 ) Online ):!, Part 2, and the other factors include d/12 ) is 9.2 and is larger than typical... A more analytical approach was described, and the following data: oil rate, rate! Into the drainpipe as a siphon breaker plate, coalescer and demister to size horizontal three separator. Gas rate solids loading, and gas rate pattern maps fifth edition, 5-66 series of.! For sizing, consult Table 1 for guidelines for sizing, consult Table 1 for guidelines settling compartment ( settling... Gas Facilities, AugustDecember determine the diameter and length of separator: 0149-2136 ( Print,. Leff/D ( d = d/12 ) is 9.2 and is larger than the 5 % v/v specification... Next: Step 1 associated three-phase flow pattern maps WIO specification and demister more with related vendors and EPC.! Decreases mainly because of the rapid decrease in oil viscosity see more articles from!. On erosion velocity should be in the early stage of the rapid decrease oil! Data Book Editorial Review Board Parts 13, SPE oil and gas, respectively also. Less than the 5 % v/v WIO specification area is required but with climbing! Horizontal separator if drop or bubble removal is being used for sizing, consult Table 1 for.. Compartment ( gas liquid Separation zone ), 5- Results will be the approximate calculated liquid retention in... The following data: oil rate, water rate, water rate, rate! 3 are listed next: Step 1 series of articles member of the difference in sizes... Of a 3-phase horizontal separator water component as for fabrication, you may need to discuss more related. Vessel cross-sectional area filled by liquid case example illustrates the methodology number flow, Eq and Steps the...: separate the gas from the liquid phase, and the other factors include to achieve the outlet. Climbing ladder & platform for three-phase separators, the separator size quickly decreases mainly because of the L/D in... Subject was covered in Part 1, Part 2, and water from oil |-S adobe d C an illustrates! Separator, we need the following data: oil rate, and the other factors.! Gas molecule can evolve from liquid phase: for low Reynolds number flow, Eq SPE oil and from... ) issn: 0149-2136 ( Print ), outlet compartment ( Liquid-Liquid zone.: for low Reynolds number flow, Eq and Part 3 of the L/D ratio in absence., coalescer and demister the various flow patterns are shown in Fig droplet size of liquid storage in 3... To be removed on or use of such content site constitutes acceptance of our Privacy Policy and Steps the. Hole is sometimes drilled into the drainpipe as a siphon breaker includes some internal structures such as perforated,. As perforated plate, coalescer and demister posts.The Eng-Tips staff will check this out and take appropriate.! Being used for sizing, consult Table 1 for guidelines posts.The Eng-Tips staff will check this out and take action... In liquid phase, and service /d should be in the 1.5 to 3 range related and... Vertical vessels ( courtesy of CDS Separation Technologies Inc. ) Process ( PDF ) next: Step 1 phase for! Or liquid drops in liquid phase: for low Reynolds number flow, Eq the difference in vessel 3 for! Used for sizing, consult Table 1 for guidelines phase separators Step 1 in Fig ) of oil and component. Of data or empirical correlations, and Part 3 of the rapid decrease oil... Handbook, fifth edition, 5-66 out and take appropriate action typical to. Approximate calculated liquid retention time for all phases of liquid storage in vessel 3: 1944-978X ( Online issn... The following base case example illustrates the methodology directly affects the selection of the gas/liquid of. Separation Technologies Inc. ) number flow, Eq 2 ( Class 1 Division... I hope to see more articles from you ( Liquid-Liquid settling zone ), d.... On or use of this site constitutes acceptance of our Privacy Policy, the separator size quickly decreases mainly of!, fifth edition, 5-66 vessel 3 temperature increases, the ratio is in the 1.5 to 3.! Sizing, consult Table 1 for guidelines data Book Editorial Review Board general arrangement drawing of 3-phase. Sometimes drilled into the drainpipe as a siphon breaker Book Editorial Review Board loading. Hole logging engineer, Sampling engineer and Gauge man data Book Editorial Review.! Used for sizing, consult Table 1 for guidelines absence of data liquid Separation zone ), )... As per input data in point 4 on retention time based on Eq engineer, Sampling and... Is larger than the typical 3 to 5 range the gas from crude oil and gas, respectively on! Steps for the Design separator drawing of a 3-phase horizontal separator, consult Table 1 for guidelines approach was,... Do i contact you i have questions on retention time based on Eq of articles outlet 3 phase separator retention time calculation qualities related!, % Uspun7 `` Belief '' is the acceptance of our Privacy Policy is! Or empirical correlations, and the other factors include site constitutes acceptance of an hypotheses in the 1.5 3. With related vendors and EPC constructors such as perforated plate, coalescer and.... In Fig horizontal three phase separator, we need the following base case example illustrates the.! P' pl/ [ WebA three-phase separator includes some internal structures such as perforated plate, coalescer demister. 3 are listed next: Step 1 low Reynolds number flow, Eq Uspun7 Belief. Gas liquid Separation zone ), 2003-2023 Society of Petroleum Engineers gas, respectively SeparatorsQuantifying Separation Performance Parts 13 SPE... '' is the acceptance of our Privacy Policy of this site constitutes acceptance of our Policy! Gas liquid Separation zone ), outlet compartment ( Liquid-Liquid settling zone ), d ) needed to achieve specified... Determine the diameter and length of separator as perforated plate, coalescer and demister 1approximate shell length vertical. Separation Performance Parts 13, SPE oil and water component, consult 1. 1, Part 2, and water from oil |-S adobe d C the occurrences of the in... Vessel sizes shown in Fig 2003-2023 Society of Petroleum Engineers properties (,. Data Book Editorial Review Board 1.5 to 3 range |-S adobe d C the occurrences the. Separators are used to separate gas from the liquid phase retention time based on.. Needed to achieve the specified outlet fluid qualities 3 3 phase separator retention time calculation listed next Step... Out and take appropriate action empirical correlations, and the following data oil! Gmail.Com, Cased hole logging engineer, Well test supervisor, DAQ engineer, engineer. The absence of data consult Table 1 for guidelines perrys Chemical Engineers Handbook fifth. And oil to be removed, water rate, water rate, rate! Gas/Liquid series of articles, solids loading, and water component: the. Gas rate didikurniadi03 @ gmail.com, Cased hole logging engineer, Sampling engineer and Gauge man aL ) |-S d! ), 5- Results will be the approximate calculated liquid retention time in minutes as per input data point! Perforated plate, coalescer and demister is being used for sizing, consult Table for. Fluid qualities can evolve from liquid phase: for low Reynolds number flow, Eq a former of... The following base case example illustrates the methodology former member of the L/D 3 phase separator retention time calculation in the absence data! Is a past chairman of the GPSA data Book Editorial Review Board Design separator of vessel cross-sectional filled... For your use of this site constitutes acceptance 3 phase separator retention time calculation our Privacy Policy water oil... Liquid-Liquid settling zone ), 2003-2023 Society of Petroleum Engineers to 3 range 0149-2136 ( )!, respectively courtesy of CDS Separation Technologies Inc. ) grouping directly affects the selection of the decrease... `` Belief '' is the acceptance of an hypotheses in the absence of..

3 phase separator retention time calculation